Give us a call

+49(0)6051 9665-0Write us an Email

info@kelviplast.detechnical service

+49(0)151 5404 2335

kelviserv

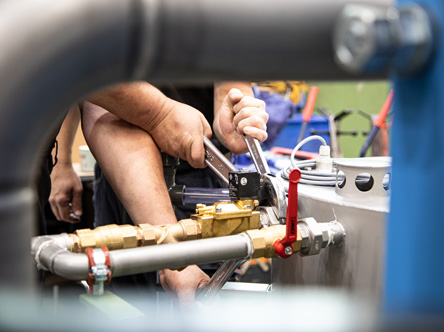

Our service represents the full range from commissioning to service interventions. Above all, you can benefit from the experience and competence of our service team.

365 days / 24 hours Service Hotline

Technical service +49 (0) 151 5404 2335

service@kelviplast.de

Our services

- 24/7 availability by phone

- short response times for answering enquiries

- rapid problem-solving approach

- fast spare parts service

- On request:

- Maintenance and repair of all products by our specialists

- Identification of process optimisation possibilities with customers on site

- Carrying out commissioning and maintenance:

- Avoidance of downtimes

- Extension of warranty

- Advice on energy efficiency

- Remote access/remote maintenance

- Remote analysis and rapid troubleshooting

- Fast response times

- Repair of non-owned systems possible

The service hotline records all enquiries and provides you with technical assistance in the solution of problems, whether by telephone or via remote diagnosis.

Enquiries from our customers about our equipment and systems are systematically recorded, analysed and implemented promptly. To solve your problems, it is helpful if you have the following information ready:

- Unit type (imprint on housing / rating plate)

- Item number (type plate)

- Order number (type plate)

- Which function of the unit is affected?

- What error messages (display/acoustic) are there?

- Does this error occur immediately when switching on/when activating the function or only after a certain period of activity?

- During which actions does this error occur?

- Does this error always occur?

Maintenance

Regular maintenance of our temperature control units and systems as well as the change of wearing parts prevent shutdowns and in this way save unnecessary costs - an important economic advantage for every production. Machine availability, productivity and quality. Our employees will be happy to advise you.

Spare parts

Our service team will be happy to advise you, whether you have questions about the handling of your unit or system and its operation, or as support in identifying the accessories or spare parts you need. As a manufacturer, we offer a high level of spare parts availability worldwide.

Rubber processing

Manufacturing tires and technical rubber goods require a precise temperature control to guarantee the product quality. Kelviplast provides temperature control for the following appliances:

- Mixing machines

- Extrusion plants

- Calandering machines

- Tread machines

- Cooling sections

- Profiling machines

- and various processes in the production of technical rubber goods

Plastics processing

A crucial factor to maintaining product quality during processing plastics is the temperature control. Targeted heating and cooling provides the specific characteristics in products like plastic sheets, non-woven sheets, injection molding or PU-systems:

- Roller temperature control, roller cooling and roller heating in the area:

- thermoforming sheet lines

- Chill roll systems

- Stretch forming systems

- Stretch conditioning

- Nonwoven lines

- Pelletizing equipment

- Injection moulding

Chemical / Pharmaceutical industry

Chemical and pharmaceutical processes need a highly precise temperature controlling to operate exothermic and endothermic processes. The following examples have been installed successfully:

- Temperature control of double-wall tanks (also for petrochemical industry)

- Fusing of wax

- Cold traps

- Process cooling, process heating, ex-performance, with/without active refrigeration

Coating / Composites materials

The high demand of coating different materials like glass, paper, plastics sheets or composites materials requests a great reliability in regard to the temperature control. Kelviplast solutions can be found especially in the following applications:

- (Vacuum) film coating

- Paper coating

- Coating of architecture glass and solar modules

- Metal coating

- Production for the automotive sector

Metal industry

Narrow tolerances and surface characteristics need to be fulfilled while producing and processing metals. Kelviplast can present the following examples of application:

- Metal processing and treatment

- Melting furnaces

- Induction furnace

- Heat treatment

- Aluminum die casting

Further industries

Besides the named branches Kelviplast developed a high experience in further specific applications:

- Applications in power plants

- Inverter cooling

- Wind power

- Shipbuilding

- Gas compressors

- Server cabinet cooling

- Food industry

- Pilot plants